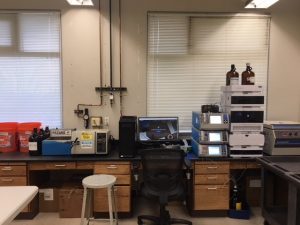

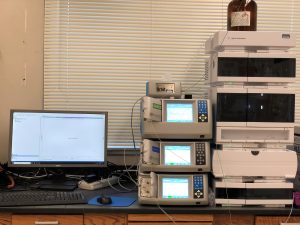

Analytical Equipment

- Liquid Chromatographs

- Gas Chromatographs

- Centrifuge

- MPLC Fraction Collector

- UV VIS NIA Spectrometer

- 400 MHz NMR Spectrometer

- Spectral Fluorometer

- Leica DM-IRM Microscope, EFOS X-Cite 50 W Metal Halide Lamp and Hamamatsu ORCA-ER Digital Camera

- Glove Box

- Vacuum Line / Dry Oven

Biomass Processing and Characterization Facilities

Ragauskas has access to the complete biomass processing laboratories that are fully equipped for a full simulation of most biomass pretreatments, pulping and bleaching processes. Chips can be prepared from wood with a Carthage chipper and screened according to size and thickness. Pretreatment and pulping studies can be done in a range of digester sizes, from a multi-unit digester system with individual 500 ml digesters to a 57 L batch digester. Our newest addition is a digester pilot-plant with a 10 L digester and four liquor accumulators capable of simulating virtually any modified kraft cooking processes. Bleaching work can be done in one of two high shear mixers simulating medium consistency processing or a pressurized peg mixer. Any type of ECF and TCF bleaching stage can be performed at low, medium, and high consistency with chlorine dioxide, oxygen, peroxide, ozone, per-acids, and biobleaching technologies. Pulp quality can be evaluated with laboratory screening and refining in either a PFI mill or Valley Beater. Fiber testing laboratory facilities provide all modern fiber testing protocols including single fiber testing, kajaani fiber length analyzer, Bauer-McNett Fiber Classifier, zero-span tensile, Fiber Quality Analyzer, and wet fiber conformability. Simulated papermaking capabilities and paper testing facilities capable of performing all TAPPI testing procedures including: kappa number, viscosity, TAPPI handsheets, tensile/TEA/tear/burst/fold and optical properties.

Additional

- Ligno-Cellulosic Processing Equipment

- BioFlo 110 O3 L) Fermentor

- Dielectric Barrier Discharge Unit

- Sherman Treater with a GX-10

- Power Generator and HT3 Power Transformer